Description

Diagnogen batch transferring peristaltic pumps can deliver fluids with up to 80% solid content through the operation mode of high-strength rotors continuously squeezing the pump tube.Industrial-grade application design,up to 9 meters suction lift, 10 Bar transfer pressure, tube life up to 2500~3000 hours,simple maintenance and low cost.It is an ideal choice to meet various long-distance, high-viscosity, high-solid content pumping requirements.

Description

Applications

Food industry Mining industry

Chemical industry Textile printing and dyeing industry

Animal food Beer, wine brewing, beverages

Sewage and industrial wastewater treatment

Cosmetics industry Fishery

Function and Feature

- Suitable for conveying fluids containing corrosiveness, high viscosity, high density, high solid content or sensitive to shear.

- Multi-layer compound tube with high transfer pressure up to 10Bar.

- Stable flow, high accuracy.

- Can transfer fluids up to 80℃.

- Can run dry and self-priming, no one-way valve, flushing system and dry-running protection, and the max suction range can reach 9 meters.

- Reverse operation can suck or discharge the blockage from the pipeline.

- The fluid only touches the pump tube, no pollution in the whole process.

- Daily maintenance is simple, generally only need to replace the pump tube.

Parameters

|

Product model

|

JP100S-20

|

JP100S-25

|

JP100S-32

|

JP100S-40

|

JP100S-65

|

|

Flow rate |

9 L/min

|

16.8L/min

|

27 L/min

|

78 L/min

|

330 L/min

|

|

Speed range

|

10~100rpm

|

10~100rpm

|

10~100rpm

|

10~100rpm

|

10~80rpm

|

|

Inlet pressure

|

≤0.9 Bar

|

≤0.9 Bar

|

≤0.9 Bar

|

≤0.9 Bar

|

≤0.9 Bar

|

|

Outlet pressure

|

≤10 Bar

|

≤15 Bar

|

≤15 Bar

|

≤15 Bar

|

≤16 Bar

|

|

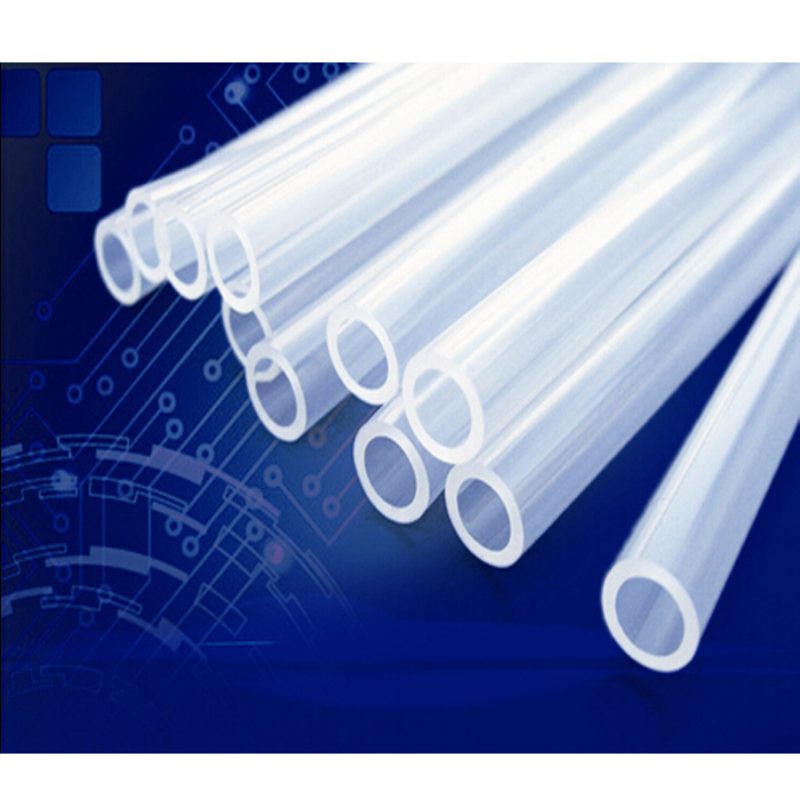

Tube material

|

NB—Standard

NBR EPDM |

||||

|

Connector

|

DN20 Pagoda

(SS304) |

DN32 Flange

(SS304) |

DN32 Flange

(SS304) |

DN40 Flange

(SS304) |

2-1/2″ Flange

(SS304) |

|

Drive model

|

AC gear motor(standard)

Explosion-proof motors(optional,Explosion-proof grade EXDIIBT4) |

||||

|

Power supply

|

three phase AC380V

|

||||

|

Power consumption

|

0.75 KW

|

2.2KW

|

2.2 KW

|

4KW

|

11 KW

|

|

Environment

|

Temperature 0~40℃, relative humidity<80%

|

||||

|

Dimension(L×W×H)

|

517×385×307mm

|

688×516×460mm

|

688×516×460mm

|

786×690×613mm

|

1170×680×1030mm

|

|

Weight

|

>50kg

|

>80kg

|

>80kg

|

>200kg

|

>700kg

|

Above flow parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure, in actually it is effected by specific factors such as pressure, medium, etc. Above for reference only.

Remarks:

• Choose pump tubing according to different material characteristics

• Pump tube life is inversely proportional to speed

• The life of the pump tube of the three materials is the same

(1)NR:Normal use, smooth inside, good wear resistance, suitable for transmission of weakly corrosive and muddy materials

(2)NBR:It is made from butadiene and acrylonitrile through emulsion polymerization, resistant to grease, alkali and detergent, and has good performance

(3)EPDM:It is a copolymer of ethylene, propylene and a small amount of non-conjugated diene. It has excellent chemical resistance, especially ethanol and strong acids.

Reviews

There are no reviews yet.